Efficient thermal management is critical in Printed Circuit Board (PCB) assembly to ensure the reliability, performance, and longevity of electronic devices. Heat dissipation challenges in increasingly compact and high-performance PCBs require strategic thermal management strategies.

1. Prevention of Component Damage

Excessive heat can damage electronic components, leading to reduced performance, premature failure, and shortened lifespan. Effective thermal management prevents overheating and maintains optimal operating temperatures.

2. Maintenance of Signal Integrity

High temperatures can affect signal integrity, leading to data errors and performance degradation. Efficient thermal management safeguards signal quality and reliability in high-speed and high-frequency applications.

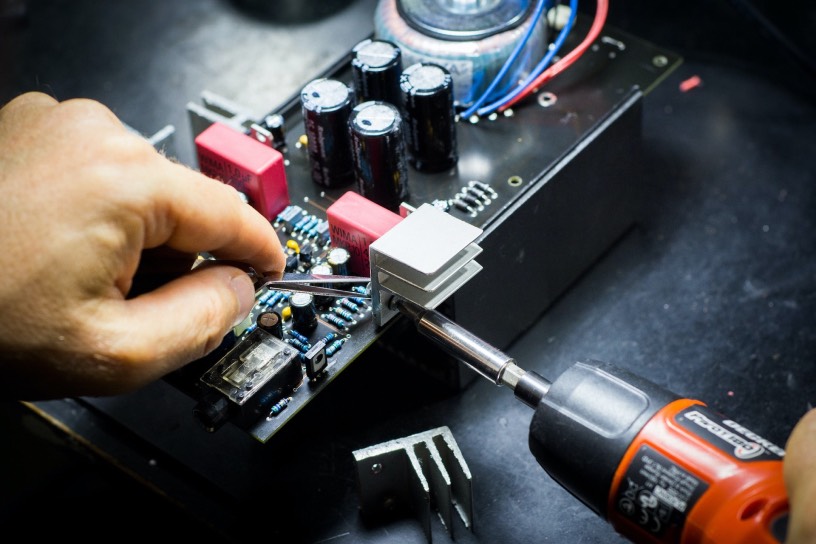

1. Heat Sinks and Thermal Pads

Heat sinks, made of materials with high thermal conductivity, dissipate heat from specific components. Thermal pads or interface materials facilitate heat transfer between components and heat sinks, improving thermal dissipation.

2. PCB Layout Optimization

Strategic PCB layout design, including component placement and routing, plays a vital role in thermal management. Grouping high-heat components, optimizing trace widths, and reducing high-current paths mitigate localized heating.

3. Thermal Vias and Plane Distribution

Thermal vias connect heat-generating components to larger copper planes or heat dissipation layers in multilayer PCBs, enhancing thermal conductivity and distributing heat more efficiently across the board.

4. Advanced Materials and Substrates

The selection of materials with higher thermal conductivity, such as metal-core substrates or ceramics, aids in efficient heat dissipation. High-performance laminates with improved thermal properties also contribute to better thermal management.

1. Active Cooling Systems

Active cooling solutions, like fans or Peltier devices, actively remove heat from electronic components. These systems are effective in maintaining lower temperatures but may add complexity and power consumption.

2. Liquid Cooling

Liquid cooling systems use coolants to absorb and dissipate heat. These systems offer high efficiency in removing heat but require careful design considerations and maintenance.

1. Thermal Simulation Software

Thermal simulation tools predict and analyze heat distribution in PCB designs before assembly. These simulations help optimize designs for better thermal performance and identify potential hotspots.

2. Thermal Testing

Real-world thermal testing verifies the effectiveness of thermal management strategies. Infrared imaging, thermocouples, and thermal chambers assess temperature distribution and validate the success of implemented strategies.

1. Integration of AI for Predictive Thermal Analysis

AI-driven predictive models will aid in anticipating and mitigating potential thermal issues, allowing for more proactive and efficient thermal management strategies.

2. Advancements in Material Science

Ongoing advancements in materials, including nanomaterials and composites with superior thermal properties, will offer more efficient solutions for managing heat in PCB assemblies.

Thermal management in PCB assembly is a critical aspect ensuring the reliability and performance of electronic devices. Employing strategic thermal management strategies, leveraging advanced materials, and embracing innovative cooling solutions will continue to be instrumental in addressing heat dissipation challenges in modern PCB designs.