The Internet of Things (IoT) has emerged as a transformative force, revolutionizing connectivity and functionality across various industries. Its impact on Printed Circuit Board (PCB) assembly is profound, shaping new requirements and driving innovations to meet the demands of interconnected devices.

1. Demand for Compactness and Integration

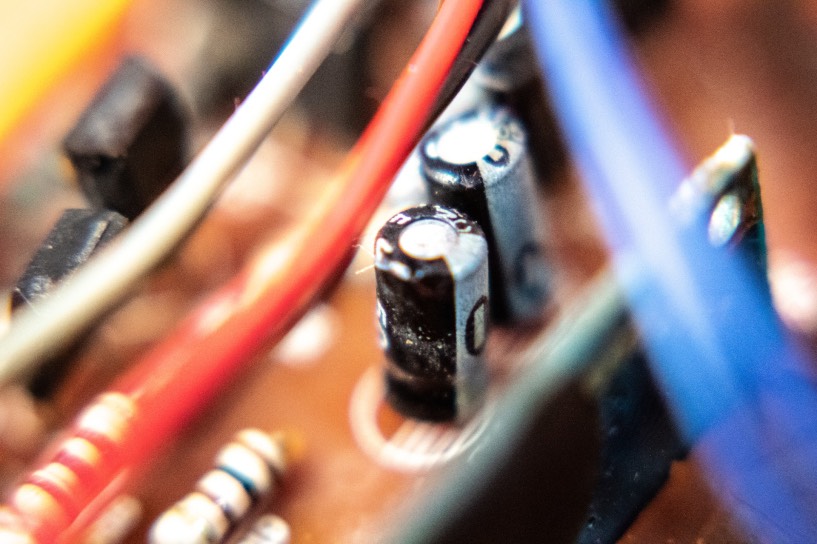

IoT devices require smaller form factors and higher integration capabilities. PCB assembly for IoT necessitates designs that accommodate numerous functionalities in compact spaces, driving the need for high-density interconnects and miniaturization.

2. Flexibility and Versatility

IoT applications span diverse sectors, from healthcare to smart homes and industrial automation. PCB assembly for IoT devices demands flexibility in designs, materials, and assembly techniques to cater to the varying requirements of different applications.

1. High-Speed and Low-Power Designs

IoT devices often operate on low power and require high-speed data processing. PCB assembly must accommodate high-frequency designs while minimizing power consumption, demanding innovative materials and efficient designs.

2. Enhanced Sensor Integration

Sensors are fundamental in IoT devices, necessitating PCBs capable of integrating various sensors seamlessly. Assembly requirements focus on accommodating different sensor types and ensuring reliable connections for accurate data acquisition.

1. Additive Manufacturing

Additive manufacturing techniques, such as 3D printing, enable rapid prototyping and customization for IoT-centric PCBs. These techniques facilitate the production of intricate designs tailored to specific IoT applications.

2. Advanced Materials

The need for flexibility, durability, and enhanced performance in IoT devices drives the adoption of advanced materials. PCB assembly requirements focus on materials offering high thermal conductivity, flexibility, and resistance to environmental factors.

1. Reliability in Harsh Environments

IoT devices operate in diverse environments, from industrial settings to outdoor deployments. PCB assembly for IoT emphasizes testing methodologies that verify reliability in harsh conditions, ensuring durability and longevity.

2. Security and Compliance

Security is a paramount concern in IoT. PCB assembly requirements encompass compliance with security standards and encryption protocols, ensuring data integrity and safeguarding against cyber threats.

1. Edge Computing Integration

IoT devices increasingly rely on edge computing for faster data processing. PCB assembly requirements will evolve to support the integration of computing elements directly onto the board, enhancing device capabilities.

2. Standardization and Interoperability

Standardization efforts will focus on ensuring interoperability among IoT devices. PCB assembly requirements will align with standardized designs and communication protocols, facilitating seamless integration within IoT ecosystems.

The IoT revolution profoundly influences PCB assembly, necessitating designs, materials, and assembly techniques that cater to the demands of interconnected devices. Embracing these evolving requirements positions manufacturers to meet the dynamic needs of the IoT era, driving innovation and connectivity across industries.