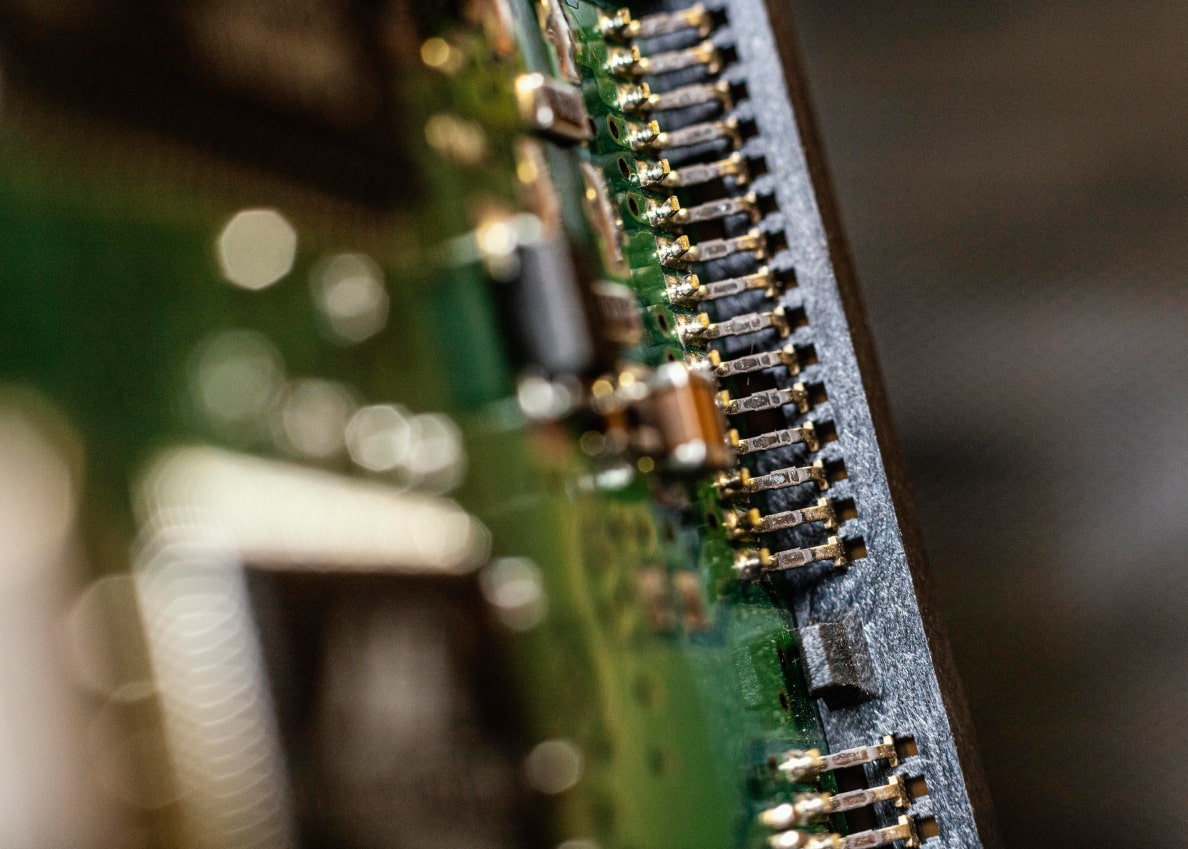

SMT (Surface Mount Technology) and THT (Through-Hole Technology) are two primary methods used for component assembly in PCB manufacturing. SMT involves mounting components directly onto the surface of the PCB, while THT involves inserting component leads through pre-drilled holes in the PCB.

SMT offers advantages such as higher component density, reduced PCB size, and improved signal integrity due to shorter interconnection lengths. Components are typically soldered using reflow soldering techniques, where solder paste is applied to the PCB pads and melted to create electrical connections during heating.

THT, on the other hand, is suitable for components that require additional mechanical support or higher power handling capabilities. Components are inserted through holes in the PCB and soldered on the opposite side using manual soldering or wave soldering techniques. THT assembly is often preferred for through-hole connectors, switches, and high-power devices.

Both SMT and THT assembly methods have their advantages and limitations, and the choice between them depends on factors such as component type, PCB design complexity, production volume, and cost considerations. Many modern PCB designs utilize a combination of SMT and THT components to optimize performance, reliability, and manufacturing efficiency.