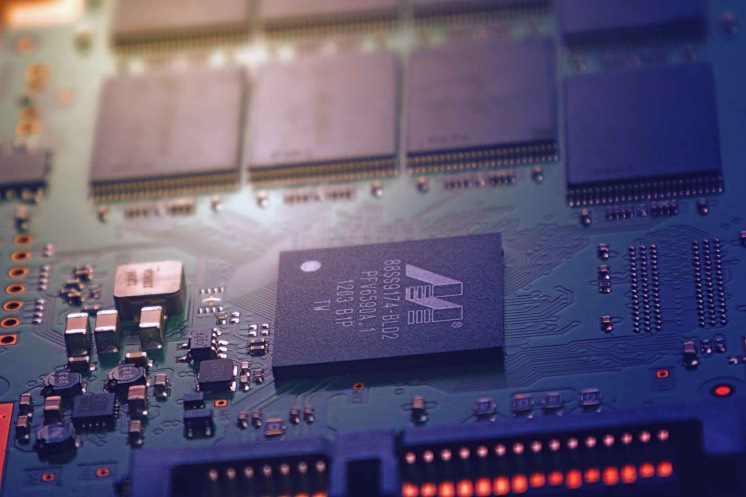

Robotics and automation have revolutionized the PCB assembly process, optimizing efficiency, precision, and throughput while ensuring consistent quality in electronic manufacturing.

In the PCB assembly phase, robotics and automation play a multifaceted role. Automated systems handle various tasks, including component placement, soldering, inspection, and handling of sensitive materials. Robotic arms equipped with high-precision placement systems accurately position components onto the PCB, enhancing assembly speed and accuracy.

Surface Mount Technology (SMT) assembly, a common technique in modern electronics, heavily relies on robotic systems. Pick-and-place machines use robotic arms to swiftly and precisely pick components from reels or trays and place them onto the board. These machines accommodate high-speed assembly lines, enabling mass production with minimal errors.

Automated soldering systems ensure consistent and reliable connections. Robotic soldering stations execute precise soldering techniques, ensuring the right amount of solder is applied with accuracy and repeatability. This level of precision significantly reduces defects and enhances overall product quality.

Beyond assembly, robotics facilitate inspection and quality control processes. Automated Optical Inspection (AOI) systems equipped with cameras and sensors detect defects in component placement, solder joints, and PCB surfaces. These systems quickly identify anomalies, ensuring compliance with stringent quality standards.

The integration of robotics and automation streamlines the entire PCB assembly process. Collaborative robots, or cobots, work alongside human operators, performing repetitive or intricate tasks with precision, while humans focus on supervisory and complex decision-making roles.

Moreover, the adoption of machine learning and AI further enhances automation in PCB assembly. These technologies analyze production data, predict failure patterns, optimize processes, and continually improve efficiency and quality.

The role of robotics and automation in PCB assembly is transformative, driving innovation and efficiency in electronic manufacturing. Embracing these technologies optimizes production lines, accelerates time-to-market, and ensures the delivery of high-quality electronic products to meet the demands of today's rapidly evolving industries.