Nanotechnology has emerged as a groundbreaking field with profound implications for PCB miniaturization and the evolution of electronic devices. At the nanoscale, materials and components exhibit unique properties that enable significant advancements in PCB design, leading to smaller, more efficient, and high-performance electronics.

One of the primary contributions of nanotechnology to PCB miniaturization is the development of nanomaterials. Nanoparticles, nanowires, and nanotubes offer exceptional electrical, thermal, and mechanical properties. Incorporating these nanomaterials into PCB substrates and conductive elements enhances conductivity, reduces signal loss, and allows for the creation of thinner, more flexible PCBs.

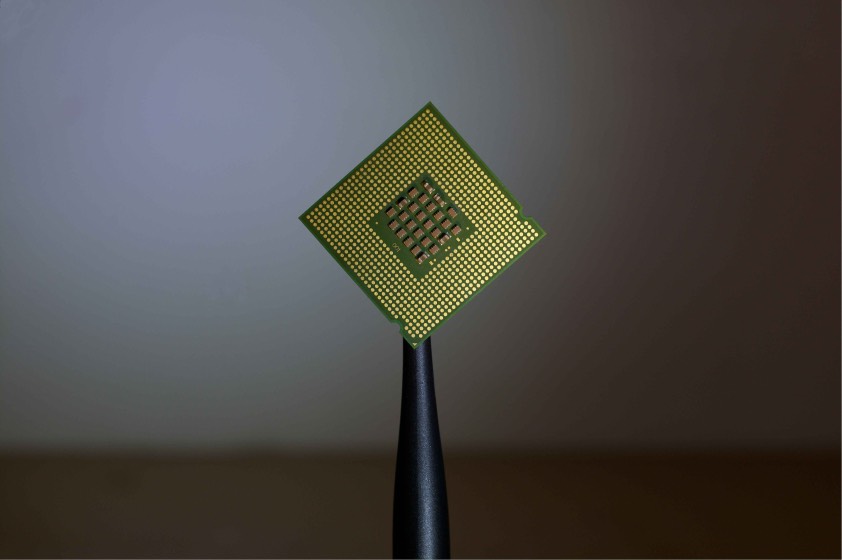

Nanotechnology enables the fabrication of nanoscale components with unprecedented precision. Nanoscale transistors, capacitors, and resistors offer superior performance characteristics while occupying minimal space on the PCB. This level of miniaturization paves the way for highly integrated circuits, enabling complex functionalities in smaller form factors.

Furthermore, nanotechnology facilitates the development of nanoscale manufacturing techniques. Nanoimprint lithography, atomic layer deposition, and nanoscale 3D printing enable the precise patterning and deposition of nanoscale features on PCBs. These techniques allow for the creation of intricate circuitry and interconnections, contributing to the miniaturization of electronic devices.

The use of nanotechnology in PCBs also enhances their functional capabilities. Nanosensors and nanodevices integrated into PCBs enable sophisticated functionalities such as environmental sensing, biomedical monitoring, and energy harvesting in compact electronic systems.

Nanotechnology's influence extends beyond miniaturization. It contributes to advancements in energy efficiency, durability, and even self-healing properties of PCBs. These innovations open doors for next-generation electronic devices with enhanced performance and reliability.

However, challenges such as scalability, cost, and mass production of nanotechnology-enabled PCBs remain. Overcoming these hurdles is crucial for widespread adoption and commercialization of nanotechnology-based PCBs in the electronics industry.

In conclusion, nanotechnology's integration into PCB design drives the miniaturization of electronic devices, offering unparalleled opportunities for enhanced functionalities, efficiency, and performance in the electronics landscape.