The relentless pursuit of smaller, more compact electronic devices has been a driving force behind the evolution of Printed Circuit Board (PCB) design and assembly. Miniaturization trends in PCBs have revolutionized electronics, enabling the development of smaller yet more powerful and versatile devices across various industries.

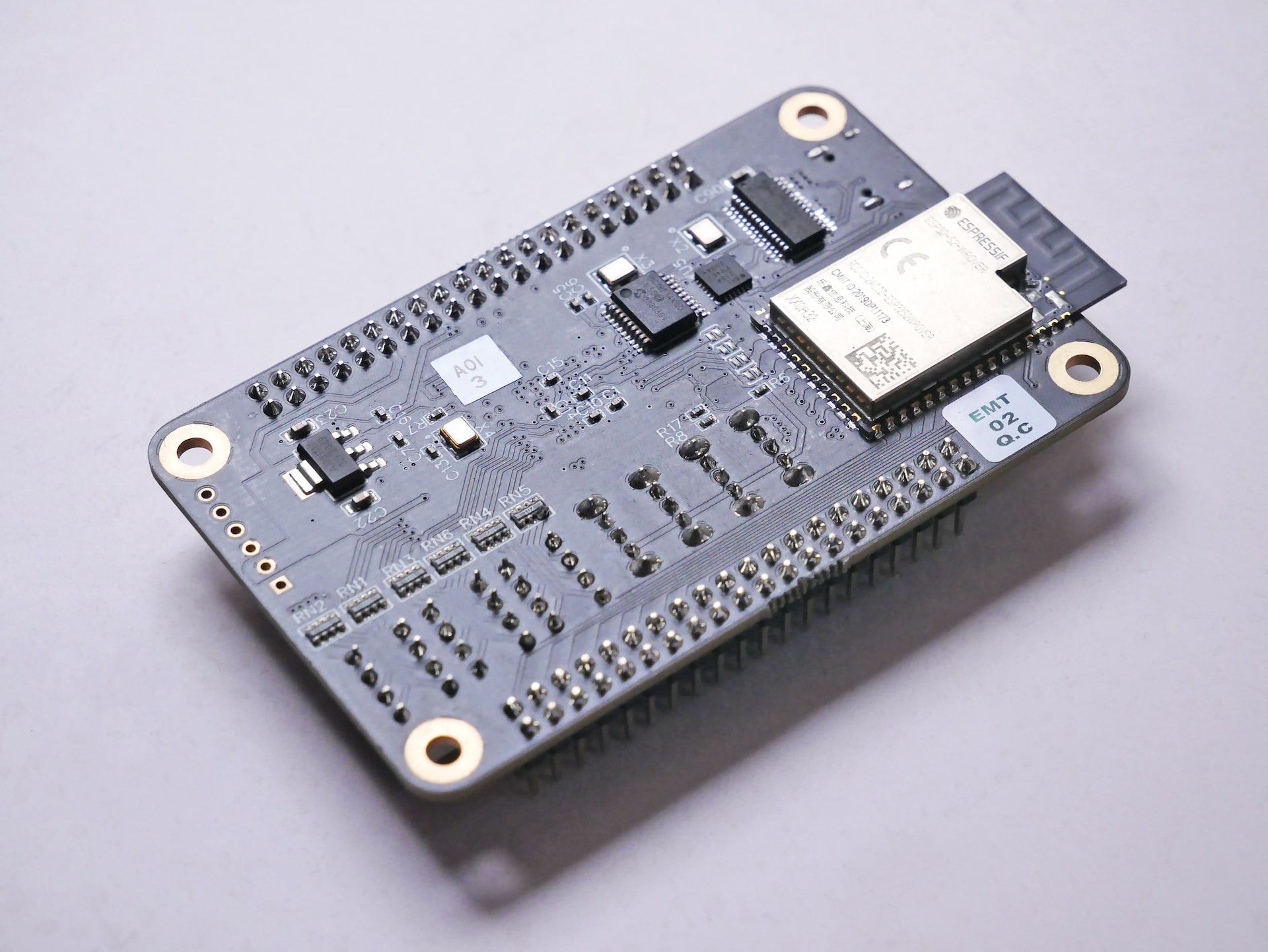

Miniaturization trends are prominently characterized by the continuous reduction in the size of electronic components. Surface Mount Technology (SMT) has been instrumental in this trend, allowing for smaller, lighter, and more densely packed components that maximize functionality in minimal space.

High-Density Interconnects (HDI) have emerged as a pivotal aspect of miniaturization in PCBs. HDI technology enables increased routing density, finer lines and spaces, microvias, and stacked vias, facilitating more complex PCB layouts and significantly reducing board sizes.

The evolution of multi-layer PCBs and flexible PCB technologies has contributed to miniaturization. Multi-layer boards accommodate more components within a smaller footprint, while flexible PCBs allow for versatile form factors and designs, especially in applications like wearables and IoT devices.

Innovations in packaging techniques, such as System-in-Package (SiP), Chip-on-Board (CoB), and 3D packaging, have played a pivotal role in miniaturizing PCBs. These techniques enable the integration of multiple functionalities or components into a single package, further reducing space requirements.

While miniaturization offers numerous benefits, it also poses challenges. Overcoming issues related to thermal management, signal integrity, manufacturing tolerances, and reliability is crucial. Advanced cooling solutions, signal integrity simulations, and robust quality control processes are essential for addressing these challenges.

Miniaturization trends have significantly impacted various industries, ranging from consumer electronics and telecommunications to healthcare and automotive sectors. Smaller and more lightweight devices with enhanced capabilities are driving innovation and transforming user experiences across these domains.

The quest for miniaturization continues, fueled by demands for more portable, powerful, and interconnected devices. Advancements in nanotechnology, additive manufacturing, and materials science are anticipated to push the boundaries further, enabling even smaller and more sophisticated electronic devices.

Miniaturization trends in PCB design and assembly have ushered in an era of compact yet powerful electronic devices. The continuous drive towards smaller form factors, higher functionality, and improved efficiency underscores the ever-evolving nature of electronics, paving the way for a future where technology seamlessly integrates into our lives in increasingly compact and innovative ways.