The field of PCBA is constantly evolving, driven by innovations and technological advancements that enhance the efficiency, quality, and capabilities of the assembly process. These developments are crucial in meeting the growing demands for more complex and miniaturized electronic devices.

One significant advancement in PCBA is the adoption of advanced automation and robotics. Automated assembly lines, equipped with high-speed pick-and-place machines, can handle the placement of tiny surface mount components with incredible precision. This not only increases the speed of assembly but also significantly reduces the risk of human error, resulting in higher quality and consistency.

Another area of innovation is the development of advanced soldering techniques. Reflow soldering and wave soldering have seen improvements in terms of precision and control, allowing for better solder joint quality and reliability. Selective soldering is another technique that provides high accuracy in soldering through-hole components, especially in complex assemblies where traditional methods might fall short.

The integration of artificial intelligence (AI) and machine learning (ML) in PCBA processes is also making a notable impact. AI and ML algorithms can analyze data from the assembly process in real-time, identifying patterns and predicting potential issues before they occur. This predictive maintenance approach helps in reducing downtime and improving overall efficiency.

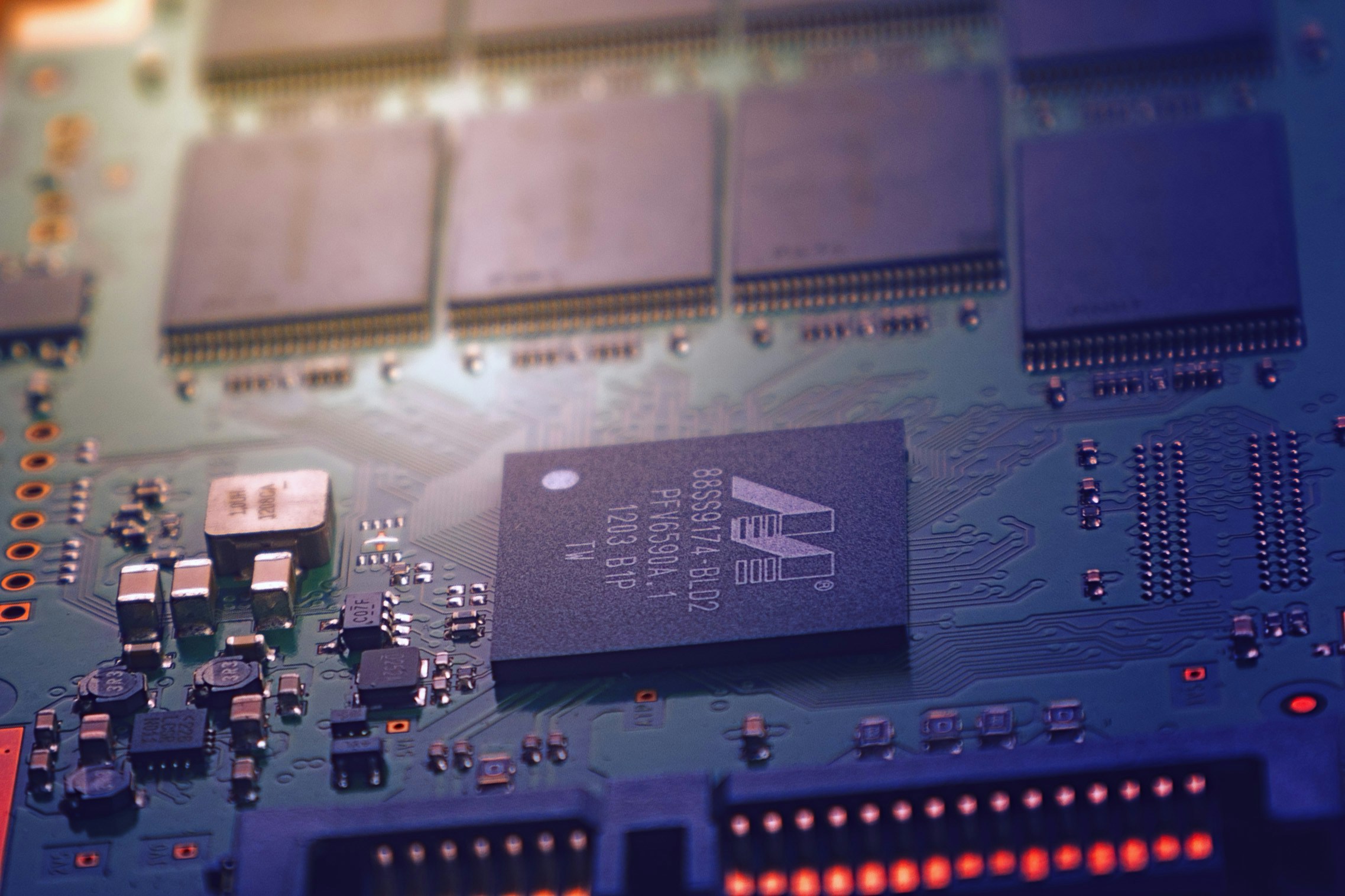

Innovations in materials and components are also shaping the future of PCBA. The development of new, high-performance materials for PCBs, such as flexible and rigid-flex boards, allows for more versatile and durable designs. Additionally, advancements in component technology, including smaller and more powerful integrated circuits, enable the creation of more compact and efficient electronic devices.

Finally, the adoption of Industry 4.0 principles is transforming PCBA services. The use of IoT devices and connected systems enables real-time monitoring and control of the assembly process, leading to better optimization and quality management.

In summary, the continuous innovations and technological advancements in PCBA are driving the industry towards greater efficiency, higher quality, and the ability to meet the increasing demands for sophisticated electronic products.