The evolution of PCB technologies continues to shape the landscape of electronics manufacturing, offering a glimpse into a future marked by innovation, miniaturization, and enhanced functionality.

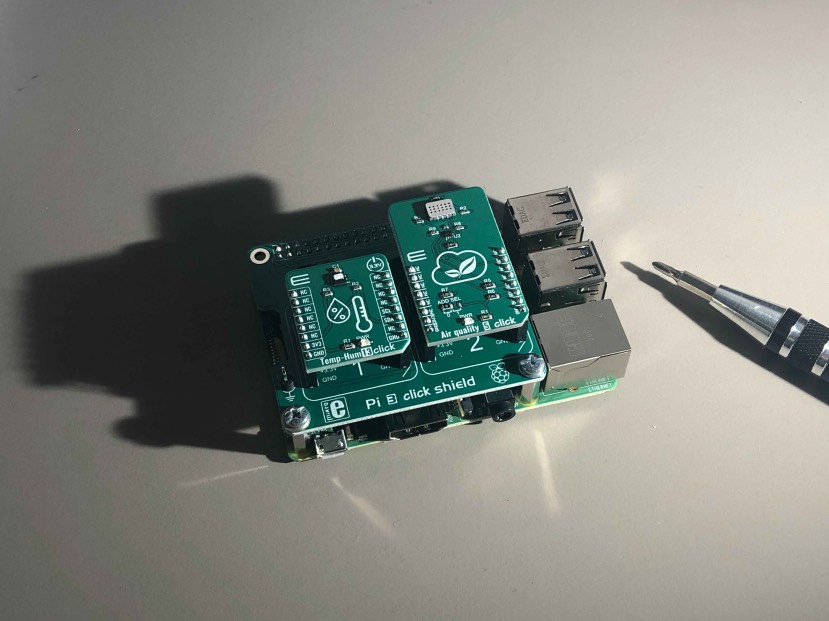

Miniaturization stands at the forefront of future PCB developments. Advanced fabrication techniques are enabling the creation of smaller, denser boards capable of accommodating complex circuitry in limited spaces. This trend towards miniaturization aligns with the demands of portable devices and IoT applications requiring compact, high-performance PCBs.

Flexible and rigid-flex PCBs are anticipated to witness significant growth. The versatility of flexible substrates allows for unique form factors, conforming to irregular shapes and enabling integration into wearable devices, automotive interiors, and medical equipment. Rigid-flex boards combine the advantages of both rigid and flexible substrates, fostering innovation in aerospace, military, and consumer electronics.

Advancements in materials contribute to the future of PCBs. Novel materials with improved electrical properties, durability, and thermal performance are being explored. Conductive inks, graphene, and nanomaterials hold promise in enhancing conductivity and reducing the size of components, driving the development of high-performance PCBs.

High-speed PCBs capable of supporting faster data transmission rates are on the horizon. These boards are crucial for applications like 5G technology, autonomous vehicles, and data centers, where high-speed and low-latency communication are imperative.

The integration of AI, machine learning, and data analytics into PCB design and manufacturing processes is anticipated to streamline operations further. These technologies optimize design iterations, predict failures, and improve production efficiency.

Sustainable and environmentally friendly PCB manufacturing methods are gaining traction. Initiatives to reduce waste, optimize energy consumption, and use eco-friendly materials reflect the industry's commitment to sustainability.

In conclusion, the future of PCB technologies is promising, driven by innovations that prioritize miniaturization, flexibility, high-speed capabilities, advanced materials, and sustainable practices. These anticipated developments will continue to revolutionize electronics manufacturing, enabling the creation of smarter, more efficient, and environmentally conscious electronic devices.