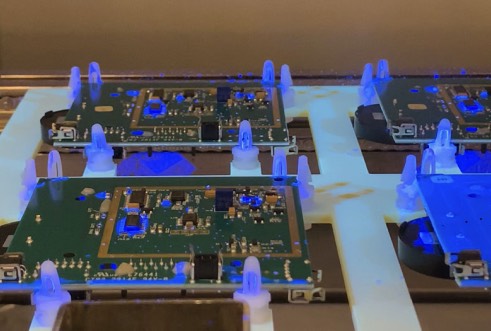

Conformal coating is a versatile solution that finds extensive use across a wide range of industries, from heavy-duty industrial applications to everyday consumer electronics. Its broad usage areas highlight its effectiveness in protecting electronic components from environmental factors and ensuring their reliability in diverse operating conditions.

In industrial applications, conformal coating serves as a critical protective barrier for electronic components used in machinery, equipment, and infrastructure. These environments often expose electronic devices to harsh conditions such as moisture, chemicals, temperature extremes, and mechanical stress. Conformal coating helps mitigate these risks by providing insulation against moisture ingress, corrosion resistance, and mechanical protection, thus enhancing the durability and longevity of electronic components in industrial settings.

Moreover, the automotive industry relies heavily on conformal coating to safeguard electronic systems and components within vehicles. From engine control units to infotainment systems, conformal coating protects critical electronics from exposure to moisture, temperature fluctuations, road vibrations, and automotive fluids. This ensures the reliable performance of automotive electronics under challenging conditions and contributes to the overall safety and functionality of modern vehicles.

In the aerospace and defense sectors, conformal coating plays a vital role in protecting electronic components in aircraft, spacecraft, and military equipment. These applications demand high levels of reliability and performance under extreme conditions, including altitude changes, temperature variations, and exposure to harsh chemicals. Conformal coating provides the necessary protection to ensure the integrity and functionality of electronic systems in aerospace and defense applications.

Additionally, conformal coating is widely used in consumer electronics, including smartphones, tablets, laptops, and wearable devices. These devices are subjected to everyday use and are exposed to factors such as moisture, dust, and physical impact. Conformal coating helps prevent damage from spills, environmental exposure, and wear and tear, ensuring the longevity and reliability of consumer electronics in various usage scenarios.

In summary, conformal coating offers versatile protection for electronic components across diverse industries and applications, ranging from heavy-duty industrial machinery to everyday consumer electronics. Its broad usage areas underscore its importance in safeguarding electronic systems and ensuring their reliable performance in challenging operating environments. By providing insulation, corrosion resistance, and mechanical protection, conformal coating enhances the durability and longevity of electronic components, contributing to the overall reliability and functionality of modern electronic devices.