The evolution of the Electronics Industry is intricately intertwined with the advancement of Printed Circuit Board (PCB) assembly processes. Over the years, PCB assembly has undergone significant transformations, adapting to technological advancements and shaping the landscape of modern electronics.

From Conventional to Advanced Assembly Techniques

1. Transition from Through-Hole to Surface Mount Technology (SMT)

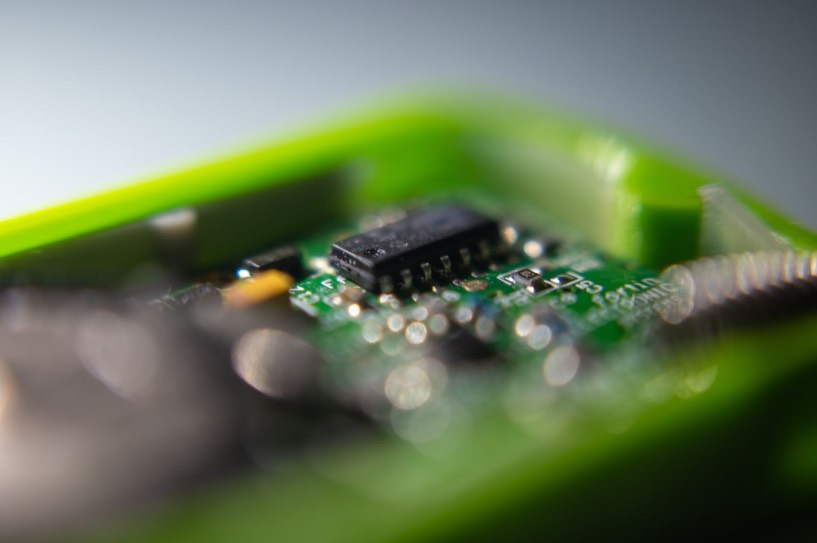

The shift from through-hole technology to surface mount technology marked a significant leap in PCB assembly. SMT introduced smaller components, higher component densities, and automated assembly, enabling more compact and efficient electronic devices.

2. High-Density Interconnects (HDI)

The emergence of High-Density Interconnects revolutionized PCB assembly, allowing for increased circuitry density and miniaturization. HDI technology facilitated the development of smaller yet more powerful devices, driving innovation in various industries.

Influence on Electronic Device Design and Functionality

1. Miniaturization and Enhanced Performance

PCB assembly advancements have enabled the creation of smaller, lightweight, and high-performance electronic devices. The compactness of PCBs allows for sleeker designs without compromising functionality.

2. Integration of Complex Functionality

Modern PCB assembly techniques enable the integration of multifunctional capabilities within a single board. Devices now incorporate diverse functionalities, such as wireless connectivity, sensors, and advanced computing, within compact spaces.

Impact on Manufacturing Processes and Efficiency

1. Automation and Robotics

Automation in PCB assembly has increased production efficiency and accuracy. Robotic systems perform intricate tasks like component placement and soldering with precision, reducing assembly time and human error.

2. Quality Control and Testing Advancements

Advancements in testing methodologies, such as Automated Optical Inspection (AOI) and X-ray inspection, ensure higher reliability and quality in PCB assemblies. Rigorous quality control measures minimize defects and enhance overall product quality.

Embracing Industry Trends and Future Directions

1. IoT and Wearable Technology Integration

PCB assembly plays a pivotal role in the proliferation of Internet of Things (IoT) devices and wearables. As demand grows for interconnected devices, PCBs evolve to accommodate diverse functionalities in compact, energy-efficient designs.

2. Focus on Sustainability and Environmental Responsibility

The electronics industry increasingly emphasizes sustainability in PCB assembly. Lead-free manufacturing processes, eco-friendly materials, and responsible disposal practices are becoming integral to PCB assembly.

Conclusion: Driving Innovation in Electronics

PCB assembly continually evolves as a driving force behind innovation in the electronics industry. Its evolution from traditional methods to sophisticated assembly techniques has shaped the trajectory of electronics, enabling advancements in device functionality, manufacturing efficiency, and interconnectedness. Embracing these advancements ensures that PCB assembly remains at the forefront of shaping the future of electronics.