Electromagnetic Compatibility (EMC) Prototyping is a pivotal stage in the electronic manufacturing services (EMS) industry, ensuring that electronic devices meet stringent EMC standards from the early stages of development. The prototyping phase allows manufacturers to identify and address potential electromagnetic interference (EMI) issues before mass production.

During EMC prototyping, engineers focus on creating a functional prototype that not only demonstrates the product's intended features but also undergoes thorough EMC testing. This involves assessing the prototype's emissions and susceptibility to external electromagnetic interference, ensuring it complies with industry standards and regulations.

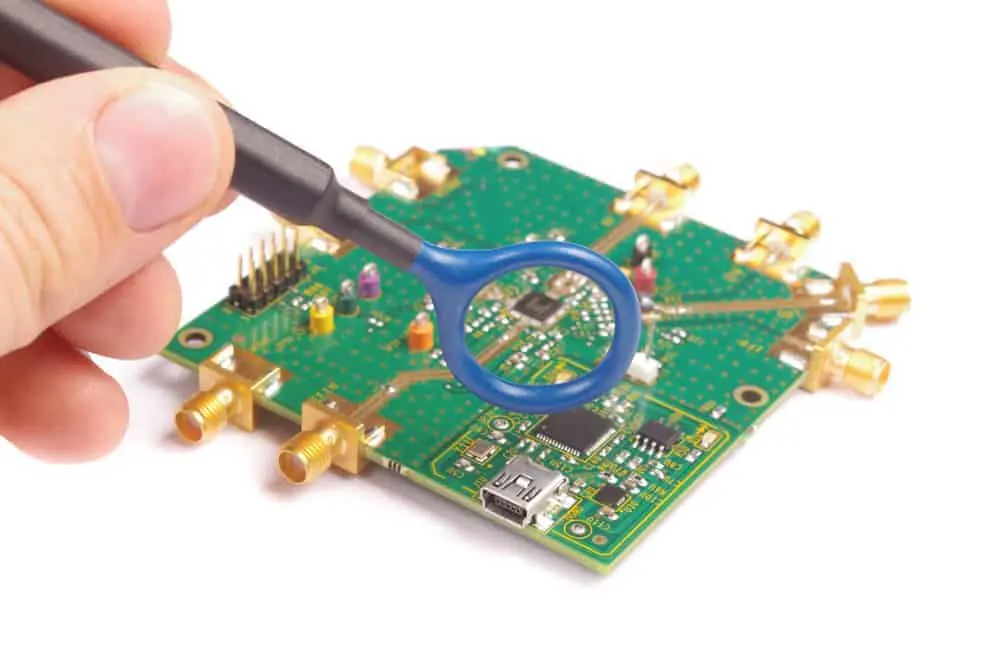

The prototyping process involves careful selection of components, trace routing, and grounding techniques to minimize EMI. Engineers may also integrate shielding solutions, such as conductive coatings or enclosures, to prevent unwanted electromagnetic radiation. Additionally, the use of EMI filters and other mitigation strategies is explored to enhance the prototype's EMC performance.

Early identification and resolution of EMC challenges during the prototyping phase are cost-effective and save time in the long run. Manufacturers can make design adjustments and optimizations based on the EMC test results, leading to a more efficient and compliant final product.

In summary, EMC prototyping is a crucial step in the development of electronic devices. It allows manufacturers to proactively address EMC concerns, ensuring that the final product not only meets performance requirements but also complies with EMC standards, guaranteeing a smooth transition to mass production.