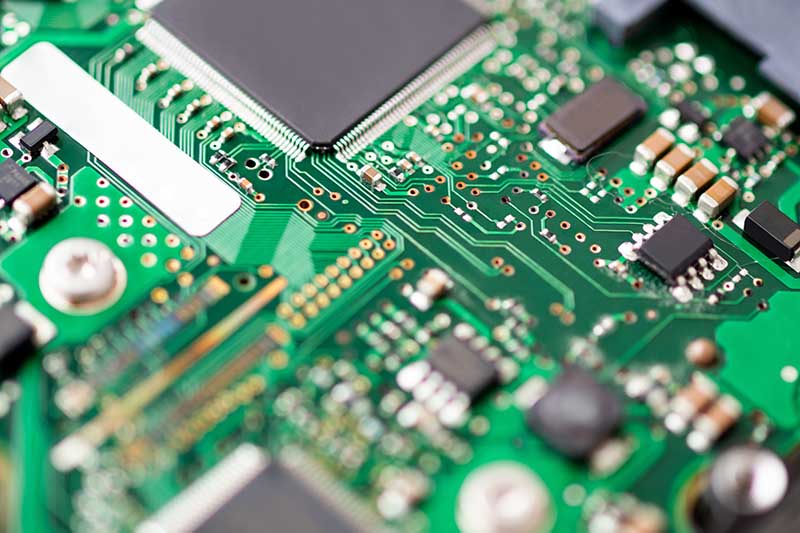

EMC (Electromagnetic Compatibility) Compliant PCB Assembly is a critical aspect of electronic manufacturing services (EMS) that directly influences the performance and reliability of electronic devices. The PCB (Printed Circuit Board) is the heart of electronic products, and ensuring its compatibility with EMC standards is paramount.

During the assembly process, various factors are considered to achieve EMC compliance. Proper component placement, trace routing, and grounding techniques are implemented to minimize electromagnetic interference (EMI) and ensure that the PCB operates within acceptable limits. EMC compliant PCB assembly involves meticulous attention to detail to create a design that minimizes radiated and conducted emissions.

Shielding strategies are often employed to prevent electromagnetic interference between different sections of the PCB or between the PCB and external components. Additionally, the use of EMI filters, decoupling capacitors, and ferrite beads helps suppress unwanted signals and enhances the overall EMC performance of the PCB.

Collaboration between design engineers and PCB assembly experts is crucial to developing a PCB layout that meets EMC requirements. Rigorous testing and validation are conducted throughout the assembly process to identify and rectify potential EMC issues. This proactive approach ensures that the final product complies with industry standards and regulations.

In conclusion, EMC compliant PCB assembly is integral to the overall success of electronic devices. Manufacturers must prioritize EMC considerations during the design and assembly phases to deliver products that not only meet performance expectations but also adhere to EMC standards, guaranteeing reliable operation in diverse environments.