Electromagnetic Compatibility (EMC) is a critical consideration in the electronic manufacturing services (EMS) sector, extending to the final assembly stage known as Box Build Assembly. This phase involves integrating various components into a complete electronic system within an enclosure, and ensuring EMC during this process is essential for the overall performance of the device.

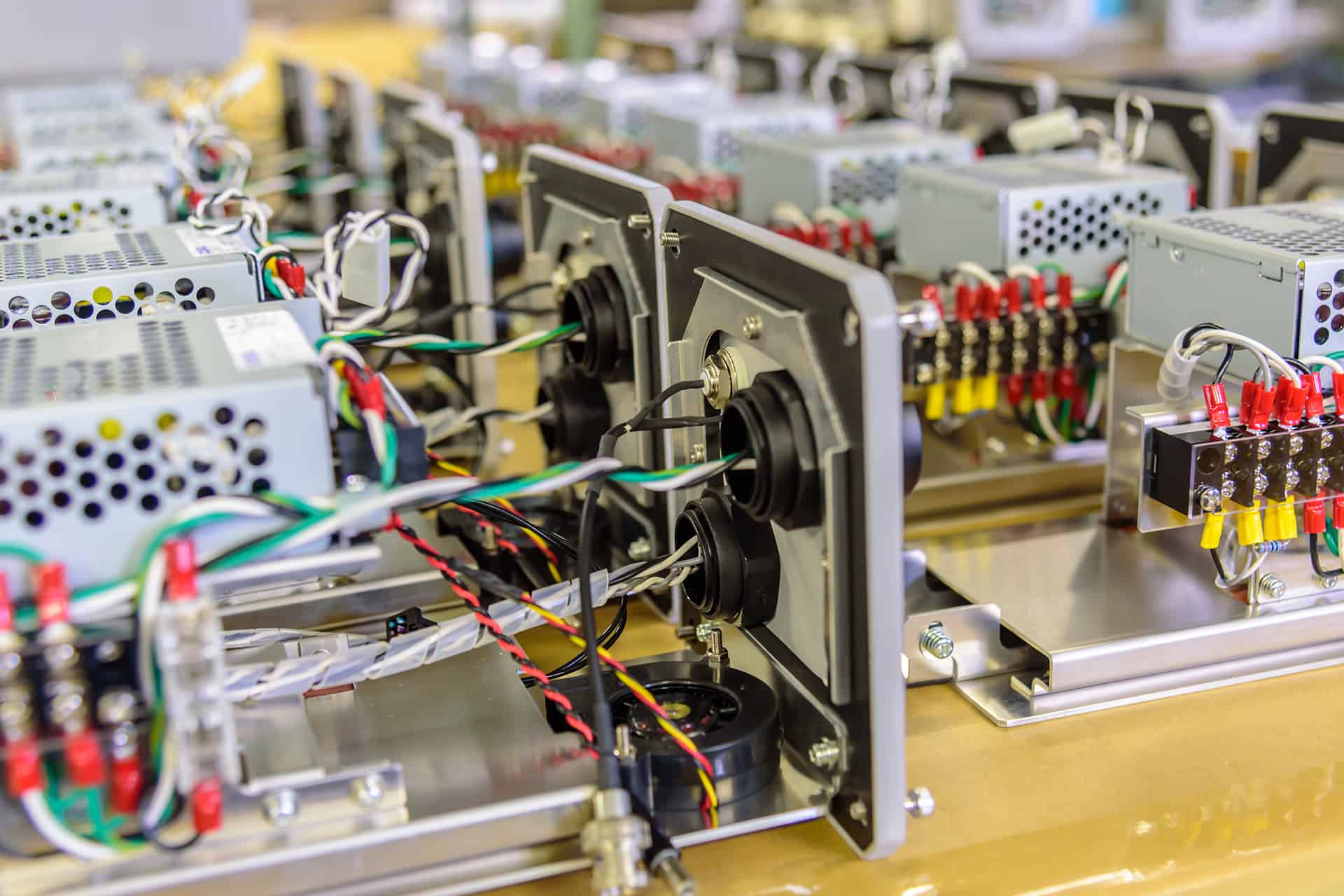

In EMC Box Build Assembly, engineers focus on minimizing electromagnetic interference (EMI) by strategically placing components, implementing effective grounding techniques, and incorporating shielding solutions within the enclosure. The goal is to create a robust and EMC-compliant system that can operate seamlessly in its intended environment.

The selection of materials for the enclosure itself plays a crucial role in EMC. Conductive materials or coatings may be employed to create a shielded environment, preventing electromagnetic radiation from escaping and protecting the internal components from external interference.

Testing and validation are integral steps in EMC Box Build Assembly. Rigorous testing protocols, including emissions and susceptibility testing, ensure that the final assembled system meets industry standards and regulatory requirements. Addressing any potential EMC issues during the assembly phase contributes to the reliability and compliance of the end product.

In summary, EMC Box Build Assembly is a comprehensive process that demands careful consideration of electromagnetic compatibility throughout the assembly of the final electronic system. By implementing effective design and testing practices, manufacturers can deliver EMC-compliant products that excel in performance and reliability.