Effective cost management is essential in the PCBA process to ensure profitability and competitiveness. By implementing efficiency and optimization strategies, manufacturers can control costs while maintaining high-quality standards and meeting production timelines.

One of the primary strategies for cost management in PCBA is efficient component sourcing. This involves working with reliable suppliers to obtain components at competitive prices without compromising on quality. Bulk purchasing and negotiating long-term contracts can help secure better pricing and ensure a steady supply of components, reducing the risk of production delays.

Another critical area is optimizing the design for manufacturability (DFM). By designing PCBs with manufacturing efficiency in mind, engineers can reduce the complexity of the assembly process, minimize material usage, and streamline production steps. This can include using standardized component sizes, reducing the number of layers in the PCB, and designing for easier soldering and inspection.

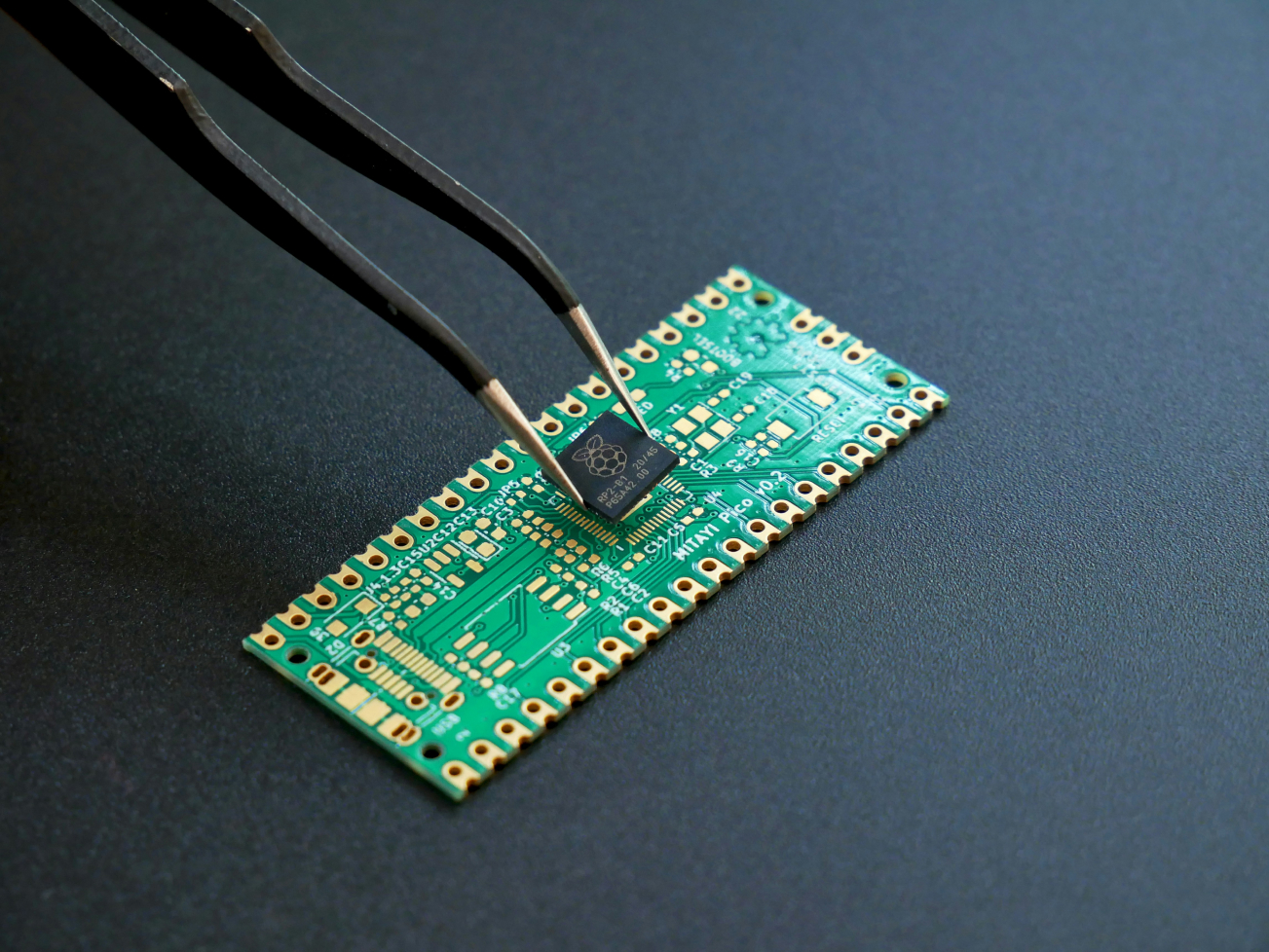

Automation plays a significant role in cost management. Automated assembly and testing processes reduce labor costs, increase production speed, and improve consistency. Investing in advanced machinery and robotics can result in significant long-term savings by reducing the need for manual labor and minimizing errors that can lead to costly rework.

Inventory management is another crucial factor. Keeping an optimal inventory level helps avoid excess stock, which ties up capital and increases storage costs. Implementing just-in-time (JIT) inventory practices ensures that components and materials are delivered as needed, reducing storage requirements and minimizing waste.

Quality control is vital in preventing costly defects and rework. Implementing rigorous testing and inspection procedures throughout the PCBA process helps identify and address issues early, reducing the risk of defective products reaching the market. This not only saves costs associated with returns and repairs but also enhances customer satisfaction and brand reputation.

In conclusion, effective cost management in PCBA involves a combination of efficient sourcing, optimized design, automation, inventory management, and rigorous quality control. By focusing on these areas, manufacturers can achieve significant cost savings while maintaining high-quality standards and meeting production demands.