Conformal coating, while primarily known for its protective qualities against environmental factors, also plays a significant role in heat management within electronic devices, directly impacting their overall performance. Understanding this relationship between conformal coating and heat management is crucial for optimizing the functionality and reliability of electronic components.

When electronic devices operate, they generate heat as a byproduct of the energy conversion processes within their components. Excessive heat buildup can lead to performance degradation, premature component failure, and even safety hazards. Therefore, effective heat dissipation is essential for maintaining optimal operating conditions.

Conformal coating affects heat management in electronic devices in several ways. First and foremost, the choice of conformal coating material can influence thermal conductivity, which is the material's ability to transfer heat. Some materials, such as silicone-based coatings, exhibit higher thermal conductivity than others, facilitating more efficient heat dissipation.

However, the thickness of the conformal coating layer also plays a critical role. While the coating provides protection, excessive thickness can act as a thermal insulator, trapping heat within the device and exacerbating temperature-related issues. Therefore, achieving the right balance between protection and thermal management is essential during the coating application process.

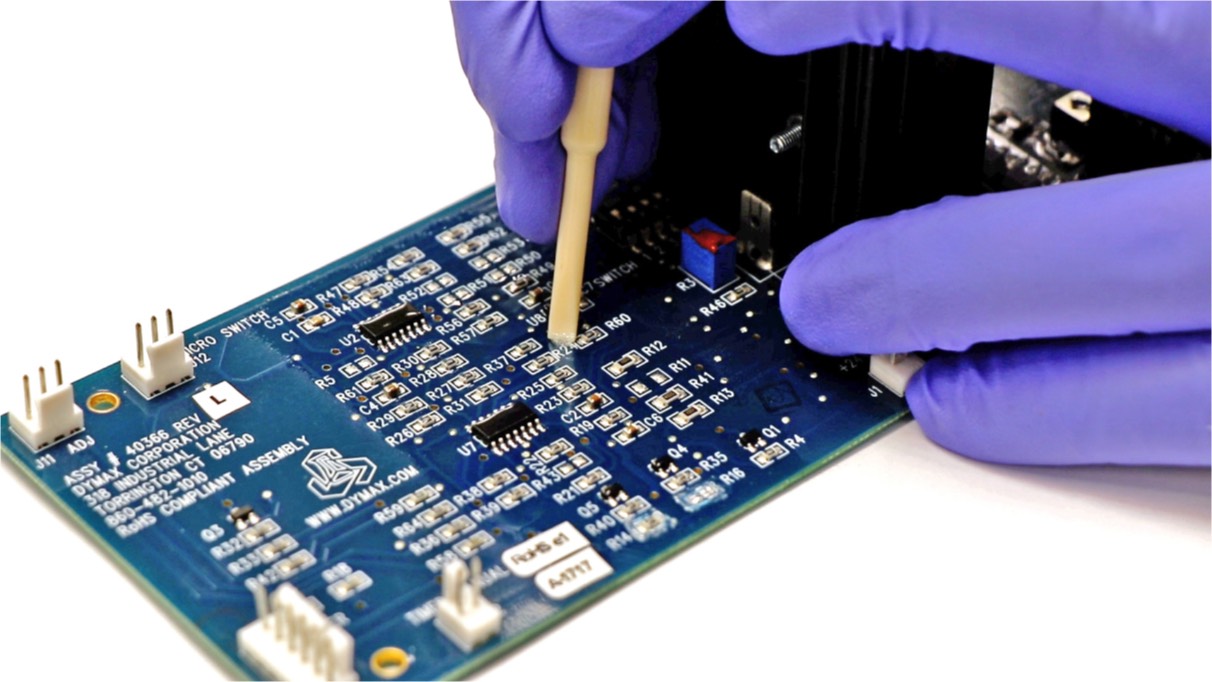

Moreover, the application method can impact heat management as well. Spray-on coatings, for instance, can result in a thinner and more uniform layer, minimizing the insulation effect and promoting better heat transfer compared to dip or brush application methods.

Furthermore, conformal coating can also influence airflow within the device. Proper airflow is crucial for dissipating heat away from critical components. Conformal coatings that impede airflow or block ventilation pathways can hinder heat dissipation and compromise device performance.

In summary, conformal coating plays a nuanced role in heat management within electronic devices. While it provides crucial protection against environmental factors, its impact on thermal conductivity, coating thickness, and airflow must be carefully considered to ensure optimal heat dissipation and overall device performance. By understanding and addressing these factors, manufacturers can effectively enhance the reliability and longevity of electronic components in various operating conditions.